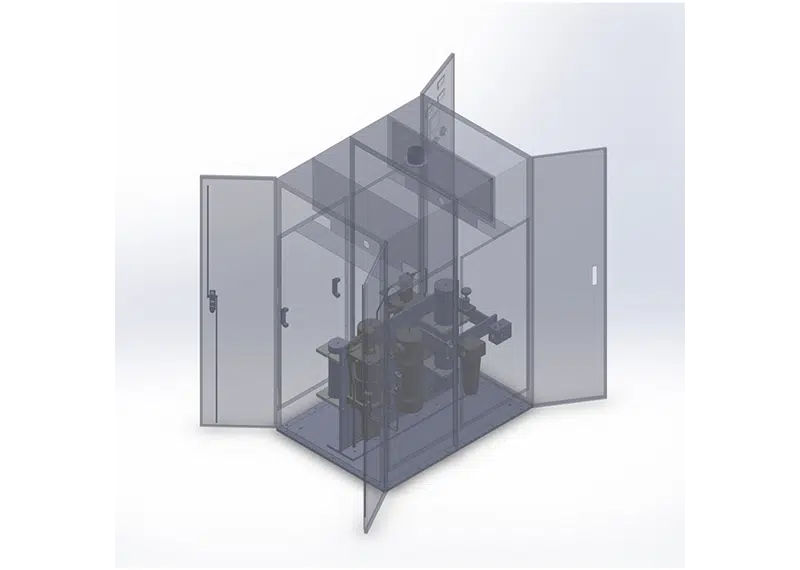

- Fields of application: Hydrogen (H2) components

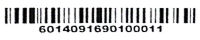

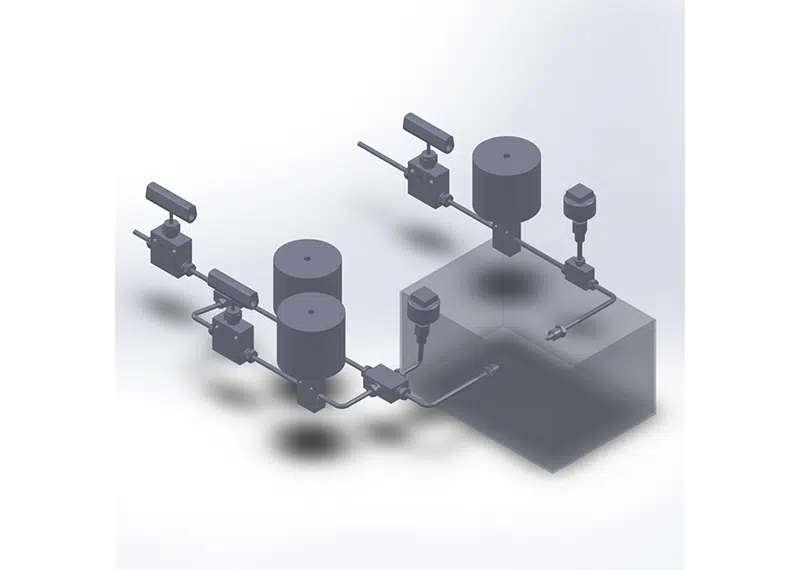

- Pressure tests according to EG79 and R134

- The gas compression chamber of the compressor is sealed from the outside through metal static seals, with a typical leakage rate designed at 10-4 mbar l/sec, requiring no special equipment. If needed, it can be designed for higher sealing performance to achieve a leakage rate of 10-6 mbar l/sec.

- The program included the following functions: high temperature, low temperature, ambient temperature, humidity, and hot cycle.

Product Traceability

Tracing the Source, Upholding Quality — All for Giving You the Best

Each gas generator is labeled with a one-dimensional barcode to enable easy traceability of its origin, ensuring both quality and management efficiency.